By adding silicon to boron carbide, body armour can be made more impact-resistant

Boron carbide Bulletproof vests can be made more impact-resistant by adding silicon to boron carbide, a material commonly used to make bulletproof vests.

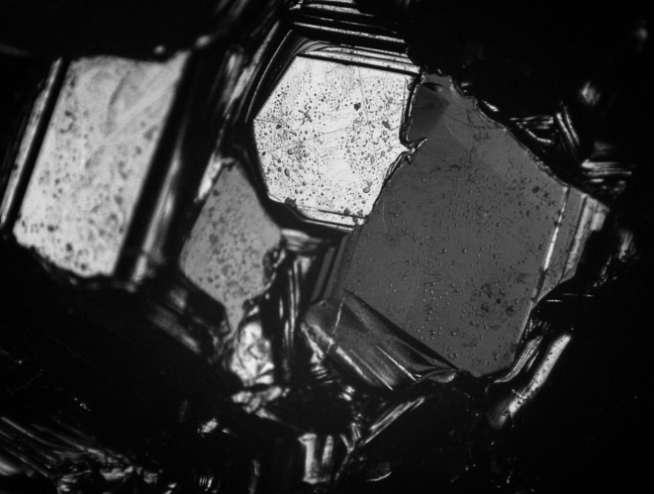

Close-up view of boron carbide crystals (image: School of Engineering, Texas A&M University) The study by Texas A&M University researchers was published in The journal Science Advances. "For the past 12 years, researchers have been looking at ways to reduce the damage caused by high-speed bullets hitting armor made of boron carbide." Dr. Kelvin Y. Xie, assistant professor, Department of Materials Science and Engineering. "Our work finally addresses this unmet need, and is a step toward designing advanced body armor that will defend against more powerful guns in combat."

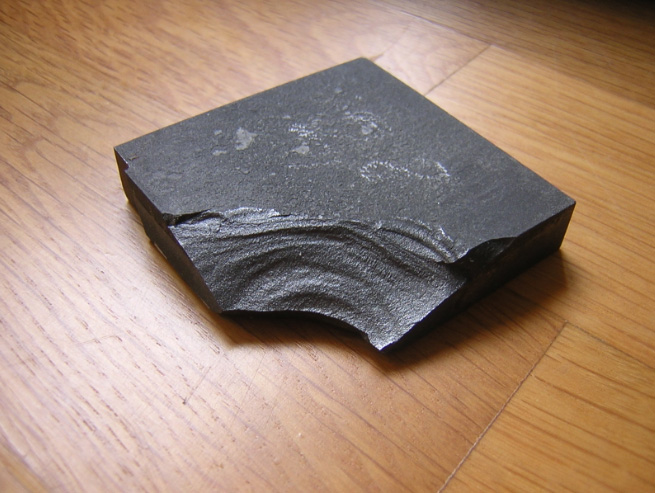

Description of bulletproof armor structure The first synthetic auxetic material that can be extended to body armour and tracksuits. Nanoscale analysis of hair could help create new body armor Known as a "black diamond," boron carbide is second only to boron nitride in hardness. Unlike cubic boron nitride, it is said to be easier to mass produce than other armor materials such as silicon carbide, and is harder and lighter, making it ideal for bulletproof vests and other armor projects. According to Texas A&M University, the main disadvantage of boron carbide is that it can be quickly damaged by a high-speed impact. "Boron carbide is really good at stopping bullets moving at 900 meters per second, so it can effectively stop most pistol bullets," Xie said in a statement. But beyond this critical speed, boron carbide suddenly loses its ballistic properties and becomes less effective."

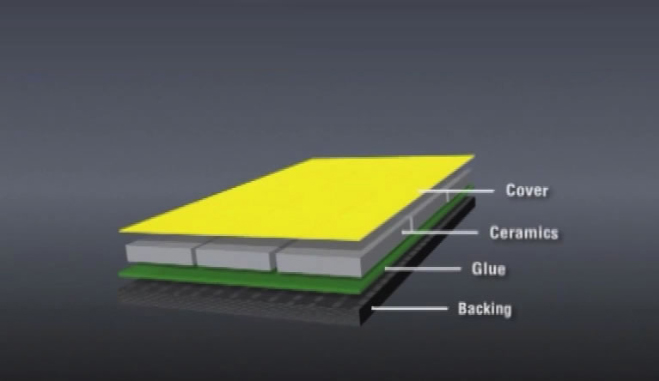

Bulletproof armor

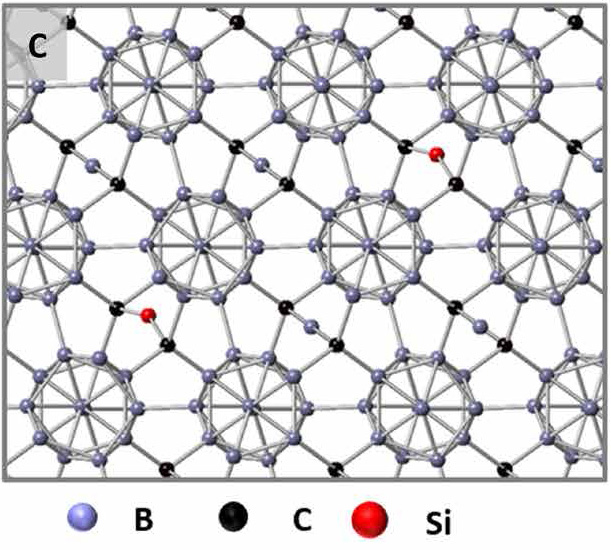

Scientists know that high-speed vibrations cause boron carbide to undergo phase transitions, in which one material changes its internal structure and presents two or more physical states simultaneously. The impact of the bullet changes the boron carbide atoms from a systematically ordered crystal state to a disordered glassy state. This glass-like state impinges on the material integrity of the contact between the bullet and the boron carbide. "When boron carbide goes through phase transitions, the glass state creates a path for the propagation of cracks," Xie says. Therefore, any partial damage caused by the impact of the bullet can easily spread throughout the material and cause more and more damage." Previous work using computer simulations predicted that adding small amounts of other elements, such as silicon, might make boron carbide less brittle. Xie and his team investigated whether adding a small amount of silicon also reduced the phase transition.

Silicon doped boron carbide crystal structure To simulate the initial impact of a high-speed bullet, the researchers made controlled indentations on a sample of boron carbide with a diamond tip. Then they used a high-powered electron microscope to look at the microscopic damage caused by the impact. Xie and his collaborators found that even with very little silicon, the phase transition was reduced by 30 percent, significantly reducing the damage caused by indentation. While silicon is good at enhancing the properties of boron carbide, Xie says more experiments are needed to see if other elements, such as lithium and aluminum, can also improve the properties of boron carbide.

|  中文

中文  にほんご

にほんご  Deutsch

Deutsch 中文

中文  にほんご

にほんご  Deutsch

Deutsch