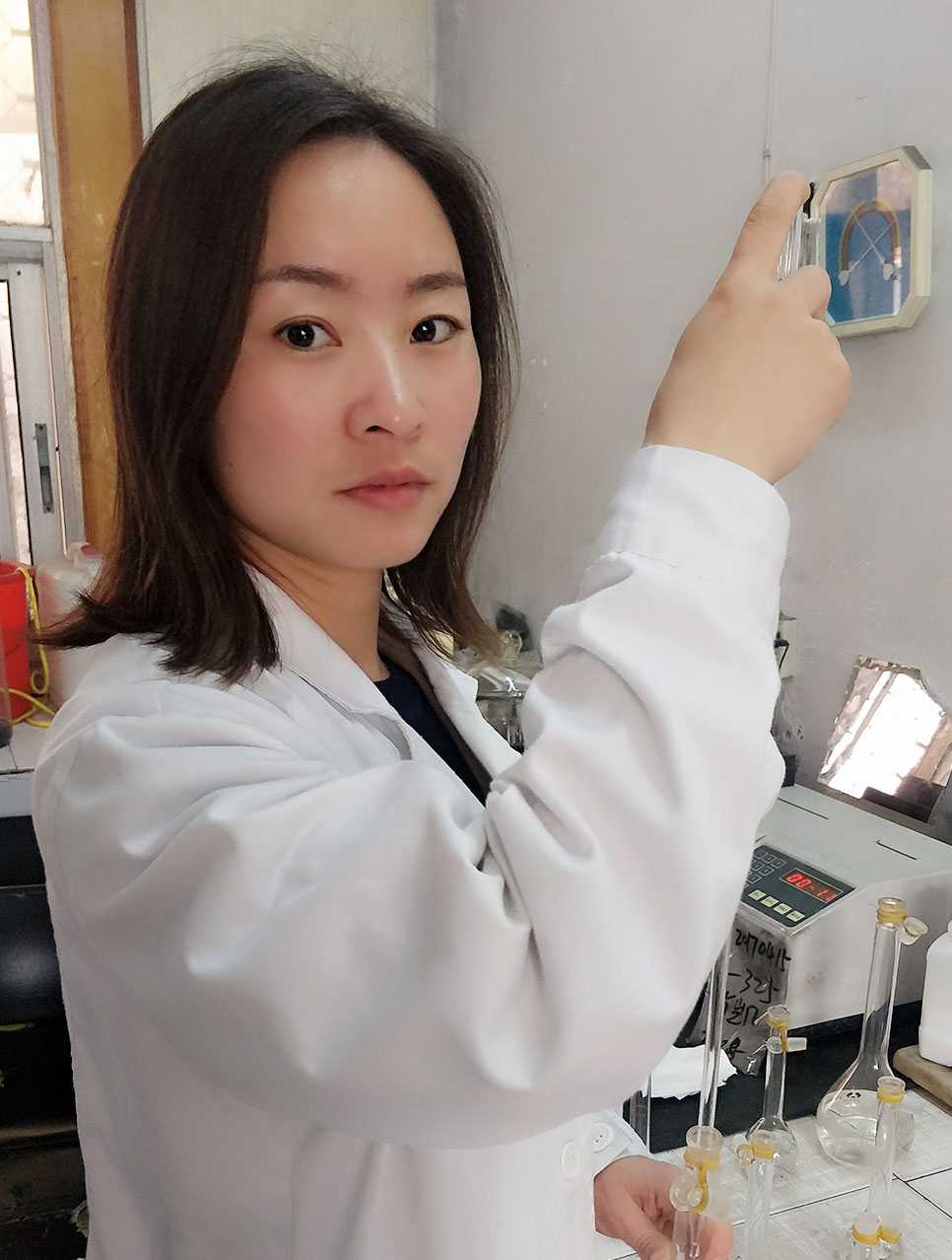

The elegance of workers

Xiao-yan wang Zhengzhou Songshan Boron Carbide Sales Co. LTD

Age: 32 years old

◎ Position: Production supervisor

What kind of job are you in?

I am now the director of the production department of the enterprise, mainly responsible for the supervision and management of production technology and product quality.

2. How long have you been in the abrasive and abrasive industry? What was your previous job or major?

I've been working in this industry for 12 years. My major is laboratory testing. 3. How did you enter the abrasive tool industry at the beginning? It all started when I was a student. When I went to school, I was very partial to science, science is very good, I am particularly interested in chemistry class to do experiments with the bottles and cans. When the college entrance examination, I applied for a chemical school, but the school transferred me to statistics and accounting major, and I felt at that time and their preferences are very far apart, did not go to read, but to zhengzhou abrasive abrasive grinding research institute to learn laboratory testing, after the completion of the study, to work in the abrasive abrasive enterprise. *** At the beginning, I worked as an analyst in the quality inspection department of the enterprise. My job was to test the quality of products. 4. How do you evaluate your job? This job is more of an interest for me, so work is a very interesting thing in my eyes. Because of the nature of the job, this job is not without care. Sometimes a small change from a chemical point of view can have a big impact on the quality of the product. Whenever There is a new discovery or new achievement, I will feel a sense of achievement. I think this is a job that can realize self-worth. 5. In your opinion, what are the most important requirements for doing this job well? I think you must be careful and attentive in your work. Earnestness will make the work more refined, and you will find a lot of skills with your heart. Under such working attitude, all problems can be well solved, and the work quality will also be improved. 6. Are you comfortable doing this job now? Now this job is what I would call handy, but the company has a lot of new projects to develop on, so to put more energy into new projects means more study and effort. Especially after the formulation of each process, I should pay more attention to each production detail and quality control in the specific implementation process. 7. What abilities or strengths do you think fit this position? I think it's careful. Because both the product quality and the production process need to be careful. If you want to know clearly what effect the improvement of the process has on the product quality, you need to observe carefully, so that the problem can be found in time. Especially in the fine powder, the requirements for product quality is more strict, if not careful, will ignore a lot of problems. 8. What is the working atmosphere like? How do you evaluate your relationship with your colleagues? Our company is especially like a harmonious big family, because there are many young people in the company, so everyone gets along with each other very relaxed and happy. Maybe this is also related to the nature of our company. We make boron carbide material, and the output of this product is not as large as that of ordinary abrasive. We emphasize more on "quality" rather than "quantity", so the production process is not so urgent. So, our working environment is relatively relaxed. 9. What do you think you get from this job? I think the process of working is also the process of learning. From the beginning of the work for abrasive products know nothing, to now dare not say proficient, but is also a half expert, I learned a lot in this process, this process can be said to be a leap. 10. Is there anything at work that sticks in your mind? When our company started to make boron carbide, we chose a smelting process that was quite different from that in the industry. At that time, all the peers used a small transformer of 630 volts, while we used a transformer of 2500 volts. Because at that time was the introduction of other people's technology, so in the proficiency is still a lot of lack. I still remember at the beginning of smelting, we did not produce a full 17 furnaces any finished products, at that time is really a fatal blow. At that time, Wang and I did not go back home for a month, and we had been studying in the company. In order to solve the problem as soon as possible, eating, sleeping rules have been disrupted, it is really busy in the dark. But when *** block boron carbide refined out, that kind of joy until now still let me remember. I felt a great sense of accomplishment because our achievement was, at that time, the first of its kind in China. 11. What expectations do you have for your future self or company? Our company's products belong to the new type of abrasive, development space is very large. In addition, there are not many domestic enterprises making boron carbide at present, so I think the future market of the company is also very broad. At present, our products are always in short supply and the order list is very full, which makes everyone in the company confident about the future development. As for my expectations, I hope I can realize more self-worth on this platform under the guidance of my hobbies and in a harmonious working atmosphere.

|  中文

中文  にほんご

にほんご  Deutsch

Deutsch 中文

中文  にほんご

にほんご  Deutsch

Deutsch